Product Features

PRODUCT FEATURES

Electronic capacitor ovens are suitable for high-temperature treatment such as non oxidative drying, packaging, curing, welding, annealing, etc. for semiconductors, optoelectronic components, energy raw materials, communication products, electromechanical products, etc.

1. The shell is made of high-quality cold plate processing, and the surface is treated with spray coating technology, forming a double door structure. Aluminum silicate fibers are filled between the shell and the studio to provide thermal insulation.

2. The oven has a layered and pushcart style interior, with a flat bottom design for easy access by the pushcart.

3. Adopting convection internal circulation air transportation method, the heat energy is well preserved, the temperature is uniform, energy-saving and time-saving, high efficiency, easy operation, automatic constant temperature, and timed baking.

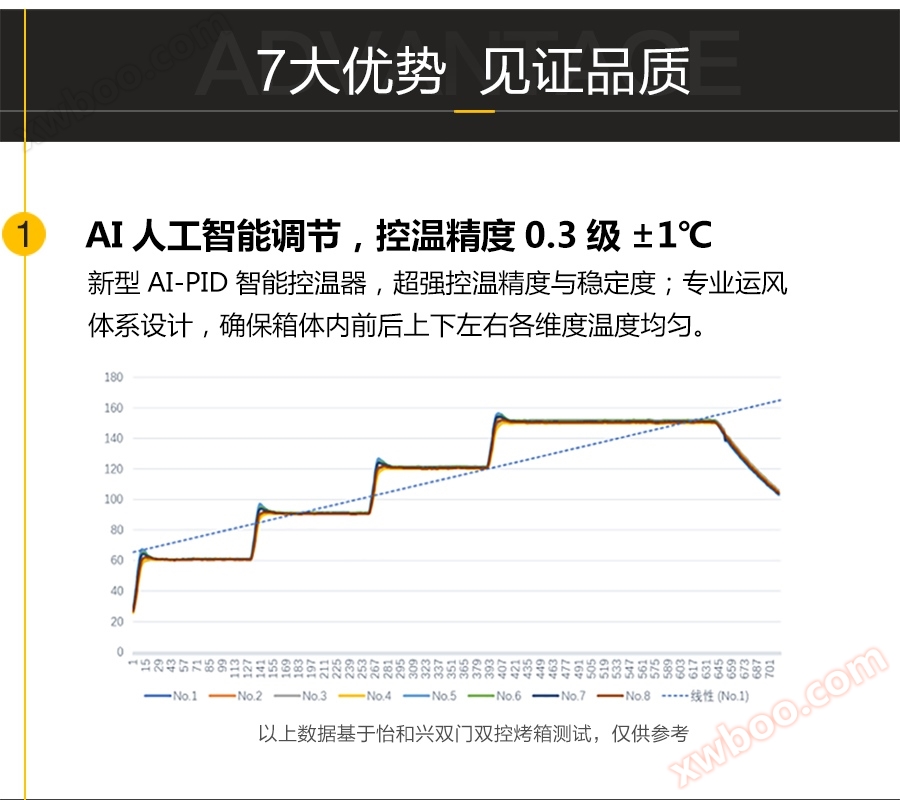

4. Intelligent PID automatic constant temperature control, capable of setting startup timing, constant temperature timing, automatic alarm and disconnection of heating element when time expires, automatic alarm and disconnection of heating element when overheating occurs, power phase loss protection, etc.

5. High density high-temperature resistant aluminum silicate thermal insulation rock wool is laid around the inner liner; It has a very good insulation effect, a complete insulation, heat insulation, and insulation scheme, and excellent baking effect.

6. Install 4 universal brake movable wheels at the bottom and equip them with 4 positioning foot cups (the height of the foot cups can be adjusted to the ground); Alternatively, a flat bottomed design can be adopted, equipped with a thousand layer rack trolley and mesh disk to provide baking efficiency and quality, which can be selected according to product characteristics.

7. Rich industry experience. Strong ability in non-standard customization, providing customers with systematic solutions for different products.

Product parameters

PRODUCT PARAMETERS

1. Temperature range: normal temperature -250 ℃, adjustable constant temperature

2. Size: Non standard customization

3. Heating rate: Raise from room temperature to 200 ℃ in about 30 minutes

4. Thermal insulation performance: The outer wall temperature does not exceed 45 ℃ (when the furnace temperature reaches 200 ℃)

5. Temperature control accuracy: ± 2 ℃

6. Temperature uniformity: ± 3 ℃%

7. Power supply: 380V/50HZ (three-phase five wire)

Core Configuration

CORE CONFIGURATION